September 15, 2025

Introduction

Drying and curing of cannabis flower is the last and potentially most important step in a months long journey from cutting/seed to the final product hitting the shelves. Research on the ideal environmental conditions for this process is limited in cannabis. One of the primary goals for any drying/curing program is preservation of vulnerable terpenes that under improper conditions can volatilize and be lost. On the other hand, drying slowly under slightly higher humidity levels can lead to an increased potential for mold and mildew growth. Each facility must understand what their equipment is capable of and what environmental conditions are possible. Trim style and available drying space will also play a critical role in what is practical and achievable in our ultimate goal of properly dried/cured flower. In this review, we will discuss the current research on environmental conditions for drying and curing cannabis flower. Please keep in mind, each facility will vary by drying techniques based on many different factors. Drying cannabis flower in some ways can truly be considered an art form taking years of experience to fully understand the nuances. The purpose of this talk is to help improve that understanding through scientific research.

Post-Harvest Processing

One of the first major steps in post-harvest processing is of course trimming. Many different trimming techniques are used throughout the cannabis industry. Historically, small scale growers would simply remove the fan leaves and break branches down so that they may be hung up to begin the drying process. In some cases, entire plants could be hung upside down for weeks at a time until they are ready for further processing. Once branches are sufficiently dried and have typically lost up to 75% of their original moisture content, flower is then removed and then hand trimmed or in some cases sent through a dry-trimming machine. Much larger facilities will likely use a wet-trimming approach in which wet flower is separated from the branches and immediately tumbled to separate sugar leaves from the rest of the flower. This flower is then placed on perforated sheets to dry. In this case, flowers typically need to be “fluffed” or moved in order to reduce the potential for flattening, especially on larger flower. Instead of drying for multiple weeks, using this approach allows for flower to dry more quickly prior to long-term storage. While this may have the benefit of reducing risk for mold and mildew growth, the more volatile terpenes may be “blown off” or lost at a higher rate. Which approach is best for operators again will depend on many other factors including available space, timing of harvests, trim team size, etc. In any case, the goal is always the same. Preserve the cleanliness and chemical profile to the best of our abilities. It can be very discouraging to spend months growing only to falter at the finish line. As is the case with any agricultural industry, the cleaner the products go into processing and long-term storage, the more likely it is to stay that way. Therefore, as we have discussed many times before, a preventative IPM plan is absolutely critical not only for actively growing plants but also for the drying and curing process still to come.

Cannabis Terpenes

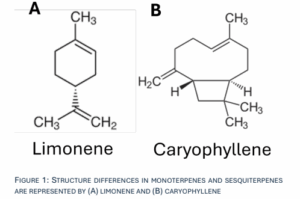

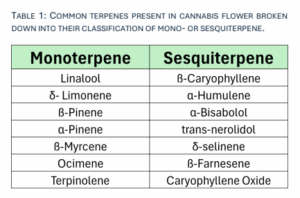

When discussing the drying process in cannabis, one of the main topics of discussion is terpene retention and preservation. As we all know, terpenes are the main compounds responsible for the aromatic characteristics of cannabis. Aromas can vary wildly from pepper/spice (ß-caryophyllene), pine (pinene), lemon/citrus (limonene), and earthy/musky (myrcene) to name a few. For the purposes of this discussion, we will not be discussing the chemistry behind terpene production (for another discussion) but instead will be focusing on terpene retention during drying. Other than THC percentages, terpene profiles are one of the main driers for sales based on desired aromas and tastes to consumers [1]. As soon as the plants are harvested, compounds such as terpenes and cannabinoids will start to decarboxylate, oxidize, isomerize, react phytochemically, evaporate, along with others [2]. Among these factors, decarboxylation is thought to be the biggest factor in cannabinoids and terpene changes over time. Another important reason to be mindful of terpene retention is the known synergistic effects of cannabinoids alongside terpenoids that enhance treatment options for pain, inflammation, and anxiety among others also known as the “entourage effect” [3, 4]. Finally, differences in terpene chemical structure can lead to differences in their stability. For example, monoterpenes are known to be more volatile when compared to sesquiterpenes [5, 6]. Monoterpenes are the simplest terpene structure consisting of 10 carbon atoms and 2 isoprene units (Figure 1). Sesquiterpenes on the other hand are more complex consisting of 15 carbon atoms and 3 isoprene units. Table 1 lists some of the most common terpenes that you will see on most certificates of analysis (COAs) in the cannabis industry. So theoretically under less-than-ideal conditions, monoterpene composition would be among the first to decline followed then by sesquiterpene concentrations.

Optimal Conditions for Cannabis Drying

The word “optimal” can be used to describe a range of temperature and humidity conditions based on local environments, available equipment, expertise, and consumer preferences. The most common temperature and humidity ranges for a traditional drying approach are 18-21oC (64 – 70oF) and 50-55% respectively. These conditions are very similar to that of a late flower room prior to harvest. Also, conditions within the room should be as dark as possible. This temperature and humidity range is typically very achievable with traditional HVAC and dehumidifier set ups. Conditions within the drying space should be monitored just as they would be in vegetative or flower rooms in order to quickly identify any potential problems. Also, while air movement may not need to be as high as within the grow rooms themselves, air movement across flower can help facilitate the drying process and also reduce the risk for mold and mildew growth.

Current research on what optimal is considered to be based on the examination of cannabinoid and terpene profiles in long-term storage is scarce. Milay et al. found that cannabis flower and contrate stored at a temperature of 4oC (39oF) were the best storage conditions based on analysis of cannabinoid and terpene preservation. These findings were also in line with other previous work that had suggested a similar temperature for long-term storage [7-9]. While it makes sense that cooler temperatures will slow any process including that of decarboxylation, these temperatures may not be realistic for large scale operations. Large-scale refrigerator systems would be required to maintain those types of temperatures consistently.

Future of Drying Techniques

Recently, research was performed using solid-state microwave (MW) technology as a means to quickly dry flower compared to traditional methods [10]. In this particular study, drying temperatures ranged from 40 – 80oC (104 – 176oF) and the authors assessed 67 different cannabinoids and 36 different terpenoids using a “traditional” drying method as a control.

Side note: full decarboxylation (conversion of THCA to THC for example) is known to occur at temperatures above 100oC (212oF) [11].

Their conclusion was that within a few hours of drying at 50oC (122oF) both the cannabinoid and terpene profiles were most similar to that of the control samples dried in a traditional manner. The authors also claim more benefits using this technology such as that more precise control of finishing moisture levels and also lower amounts of microbial growth compared to longer traditional methods. Therefore, this approach may be useful for very high production facilities and/or situations in which microbial growth is a constant concern.

Another future potential technology that can be utilized for drying is referred to as “controlled atmosphere drying chambers”. This approach allows for precise control of temperature, humidity, and specific gas composition within the chamber (CO2, O2, N2 as examples) [12]. A recent research study utilizing this technology on cannabis flower concluded that drying and curing time was reduced by 60% compared to a traditional drying technique. When using a gas combination of C5O5 (5% CO2, 5% O2, and 90% N2) monoterpenes were preserved better compared to sesquiterpenes when subjected to pure N2 within the chamber. One of the greatest potential benefits of controlled atmosphere drying chambers may be the

customization of drying conditions for individual genetics. However, what is still somewhat unclear to me is the size of the chambers that were used in this particular study and how applicable this technology again would be on a large scale. Finally, other techniques that are starting to become more researched for their potential use in the cannabis space include “hot air” (HA) and infrared (IR) heating. Both of these approaches have been utilized on other crops with varying success rates [13].

Conclusions

Drying and curing of cannabis flower is among the last and most important steps of the cultivation pipeline. Months of time and energy spent on producing the highest quality flower can all be for not if conditions within he drying space are not conducive to proper drying conditions. As discussed here, drying techniques used will vary based on trim style, available space, and also equipment. Conditions may also need to vary based on bud size and structure. Larger, more dense flower may need quicker dry times compared to smaller, less compact flower. Finding the right conditions for any cultivation setting requires experience and fine tuning to reach the maximum potential. Cultivation operations that are maintained at a high level in terms of cleanliness can still utilize traditional drying methods to produce high quality flower. One potential downside of a traditional approach is consistency. Even within indoor environments, seasonal variability can be present due to changes outside of the facility. Newer drying technologies may reduce the variability and lead to a more “consistent” cannabinoid and terpene profile however scalability may be an issue. Overall, cultivators should use an approach that makes them feel most comfortable. Small scale R&D can be a great way to experiment with new techniques prior to making a large-scale commitment to a newer technology. Next week we will discuss how biotechnology is being used to improve all aspects of cannabis cultivation for the future. If you have any suggestions of topics you would like to see covered here, please let us know. As always, please feel free to reach out with any questions or comments about the topics presented.

References

1. Gilbert, A.N. and J.A. DiVerdi, Consumer perceptions of strain differences in Cannabis aroma. PLOS ONE, 2018. 13(2): p. e0192247.

2. Milay, L., et al., Metabolic Profiling of Cannabis Secondary Metabolites for Evaluation of Optimal Postharvest Storage Conditions. Frontiers in Plant Science, 2020. 11.

3. Russo, E.B., Taming THC: potential cannabis synergy and phytocannabinoid-terpenoid entourage effects. British Journal of Pharmacology, 2011. 163(7): p. 1344-1364.

4. Namdar, D., et al., Terpenoids and phytocannabinoids co-produced in Cannabis sativa strains show specific interaction for cell cytotoxic activity. Molecules, 2019. 24(17): p. 3031.

5. Barreira, L.M.F., et al., The importance of sesquiterpene oxidation products for secondary organic aerosol formation in a springtime hemiboreal forest. Atmos. Chem. Phys., 2021. 21(15): p. 11781-11800.

6. Hellén, H., et al., Long-term measurements of volatile organic compounds highlight the importance of sesquiterpenes for the atmospheric chemistry of a boreal forest. Atmos. Chem. Phys., 2018. 18(19): p. 13839-13863.

7. Trofin, I.G., et al., The influence of long-term storage conditions on the stability of cannabinoids derived from cannabis resin. Rev Chim Bucharest, 2012. 63(4): p. 422-7.

8. Trofin, I.G., et al., Influence of storage conditions on the chemical potency of herbal cannabis. Rev. Chim, 2011. 62(6): p. 639-645.

9. Zamengo, L., et al., The role of time and storage conditions on the composition of hashish and marijuana samples: A four-year study. Forensic science international, 2019. 298: p. 131-137.

10. Uziel, A., et al., Solid-State Microwave Drying for Medical Cannabis Inflorescences: A Rapid and Controlled Alternative to Traditional Drying. Cannabis and Cannabinoid Research, 2022. 9(1): p. 397- 408.

11. Dussy, F.E., et al., Isolation of Δ9-THCA-A from hemp and analytical aspects concerning the determination of Δ9-THC in cannabis products. Forensic science international, 2005. 149(1): p. 3-10.

12. Birenboim, M., et al., In Pursuit of Optimal Quality: Cultivar-Specific Drying Approaches for Medicinal Cannabis. Plants, 2024. 13(7): p. 1049.

13. Chen, C., et al., Effect of hot air and infrared drying on the retention of cannabidiol and terpenes in industrial hemp (Cannabis sativa L.). Industrial Crops and Products, 2021. 172: p. 114051.

Featured Photo by Mark, CC BY 2.0, via Wikimedia Commons