January 14, 2025

We often hear concerns from our customers about “photobleaching.” No one wants their cannabis to come out “bleached.” It just doesn’t look right. We asked the experts here at JumpLights and Due Diligence Horticulture for their thoughts on how to avoid this gnarly phenomenon and how to help you achieve better results.

What Is Photobleaching?

Let’s start with a photobleaching definition. Photobleaching occurs when excess light energy causes the loss of green pigment—chlorophyll—in plants, making flowers turn white. In most cases, it’s just a cosmetic issue and does not significantly impact yield, terpenes, or quality. However, photobleached flowers may lead to the perception of poor quality among users, making it more difficult to sell the product. When dried and sold, photobleached buds can look brown, causing customers to think the product was not grown to a high standard. For most customers, brown equals dead or rotten. And as we all know, that’s not good.

What Causes Photobleaching?

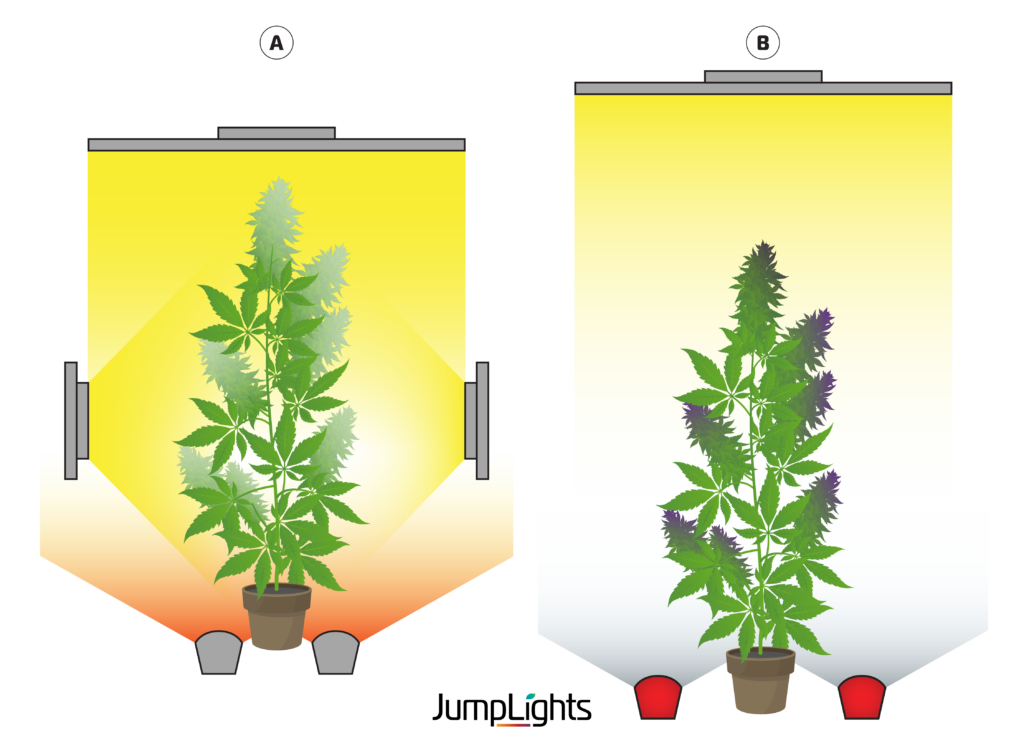

While the exact mechanism that causes photobleached plants is not completely understood, plants grown under a high fraction of red light and/or high light intensity are more likely to develop photobleached flowers. It’s been proposed that the culprit is the total red light delivered—not the fraction of red or total light intensity—that drives the photobleaching response.

Exceeding a daily red light integral, or total red light delivered over a day, of 20 mol/m2/d can lead to the photobleached effect. For example, a fixture with 50% red that delivers a daily light integral (DLI; 400 to 700 nm) of 40 mol/m2/d would deliver a daily red light integral of 20 mol/m2/d, but a fixture with 80% red would exceed the daily red light integral at a DLI of only 25 mol/m2/d. There are, however, clear and notable differences among cultivars in their susceptibility to photobleaching, i.e., some varieties never develop photobleached flowers while others are photobleached well below the daily red light integral threshold of 20 mol/m2/d.

How to Avoid Photobleached Cannabis

Our customers often ask us what they can do to avoid photobleached plants. Our first answer is always to buy the right kind of lights, like the Budkicker (over-canopy) and Catalyst (under-canopy) lights from JumpLights. In addition to working with us here at JumpLights, here are some general tips about how you can avoid the photobleach problem.

- Utilize broad spectrum light: Under balanced spectrum light, plants should not experience the photobleached effect at commonly used PPFD levels.

- Use appropriate light intensity: If you’re using a red-heavy spectrum instead of a broad spectrum, you can avoid photobleached cannabis by reducing light intensity. You can, however, use higher red when appropriate, such as in supplemental lighting situations in a greenhouse.

- Improve light distribution: Make sure light distribution is uniform to avoid areas of high light intensity at the top of the canopy.

- Get your distance right: In general, you should keep your plants at an appropriate distance from the light source. The right distance can vary based on what you’re growing and where. If you’re using under-canopy lights, take care to ensure you’re using a balanced spectrum and that you place your lights far enough away from the plants. With under-canopy lighting, you can only get so far away from the plants, so make sure to choose an appropriate spectrum like the 3A and 5A spectrums used by JumpLights Catalyst under-canopy lights.

- Use appropriate temperatures: Higher temperatures can make the photobleached effect worse, so ensure your plants are kept at an appropriate temperature. You may need to change your HVAC setup or usage to accomplish this.

The JumpLights Solution: Using an Optimized Spectrum

JumpLights takes photobleaching avoidance seriously. Our under-canopy lights are broad spectrum, with 35% and 52% red options available. We believe these spectra are ideal for improving yield and avoiding photobleached cannabis. Our over-canopy lights use a full spectrum and are easy to hang an appropriate distance away from the plant. We’ll always work with you and your team to ensure everything is executed properly!